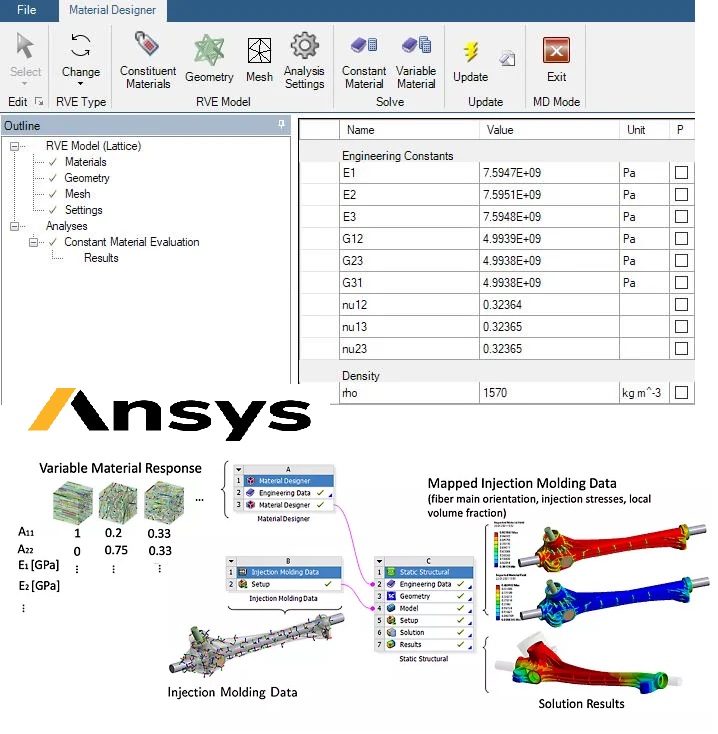

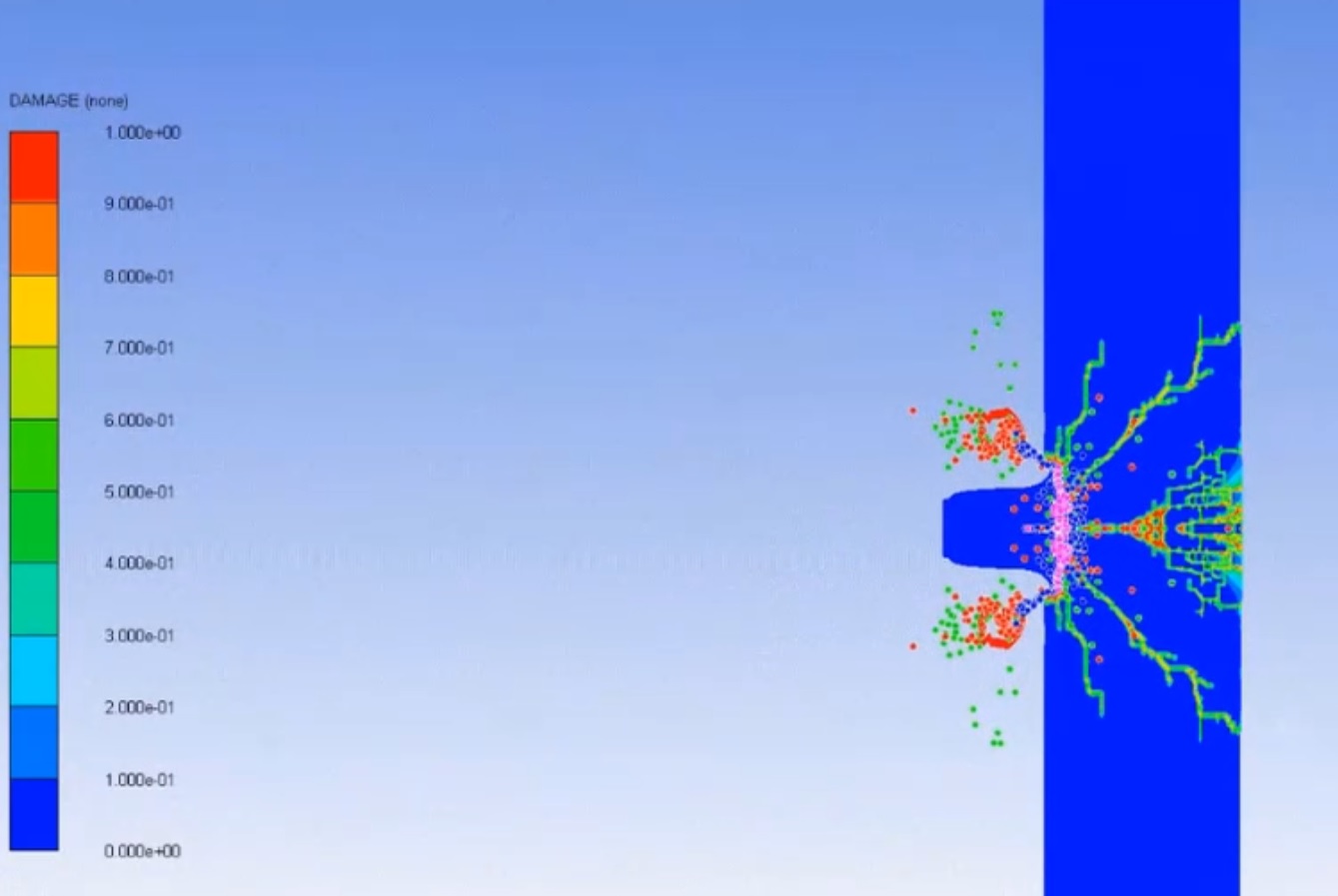

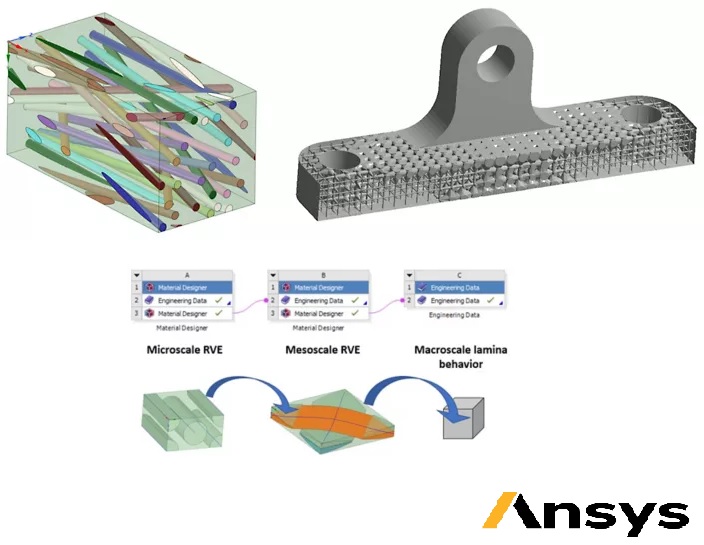

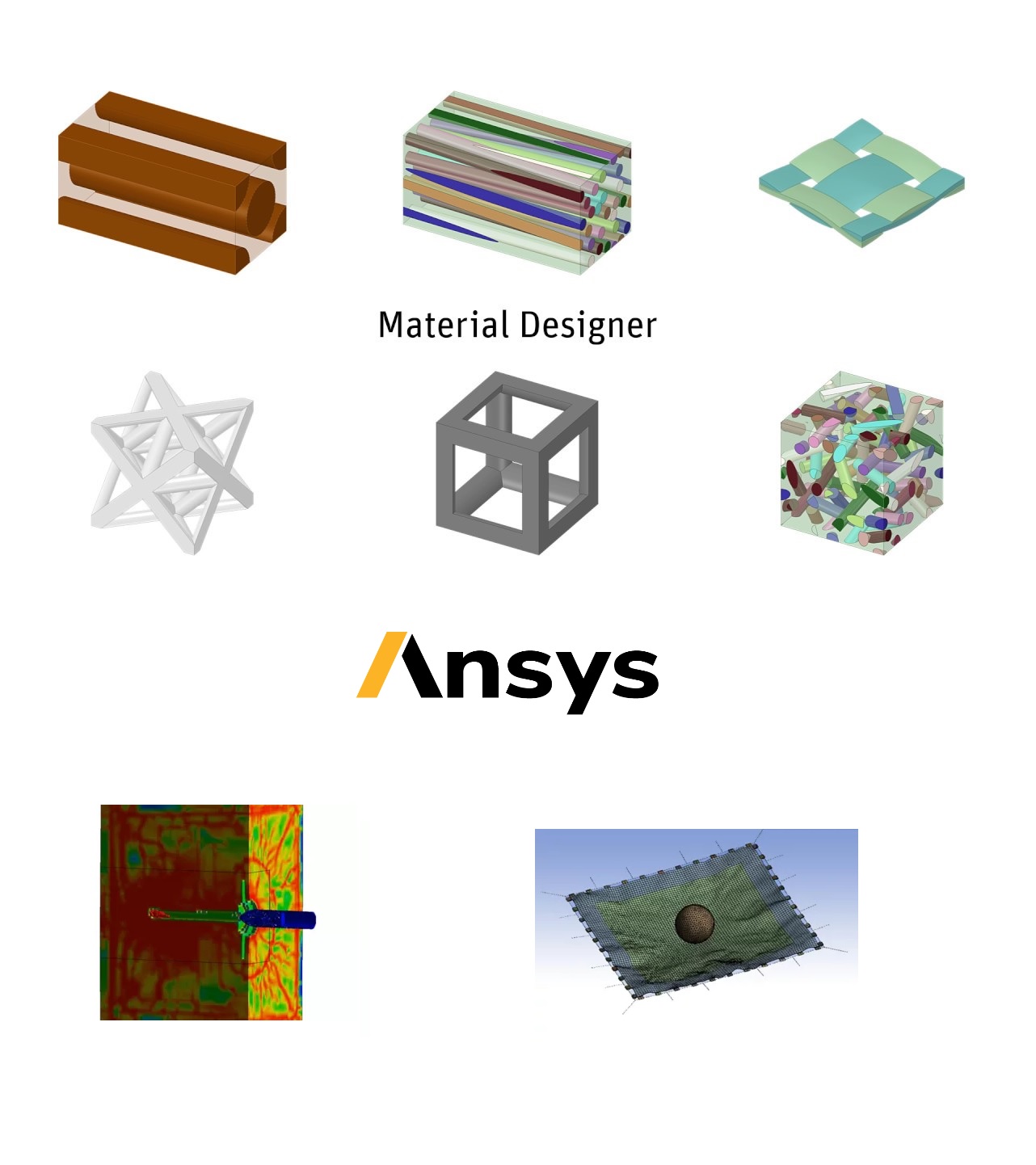

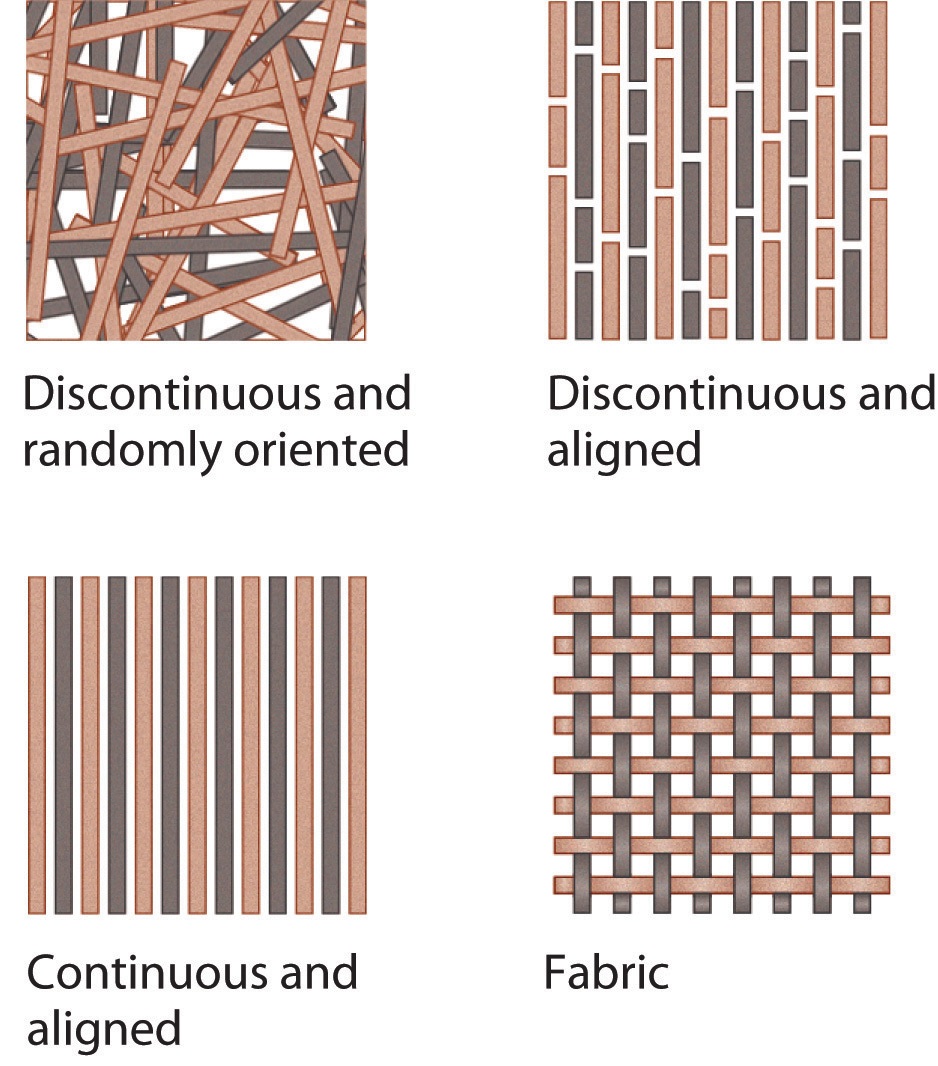

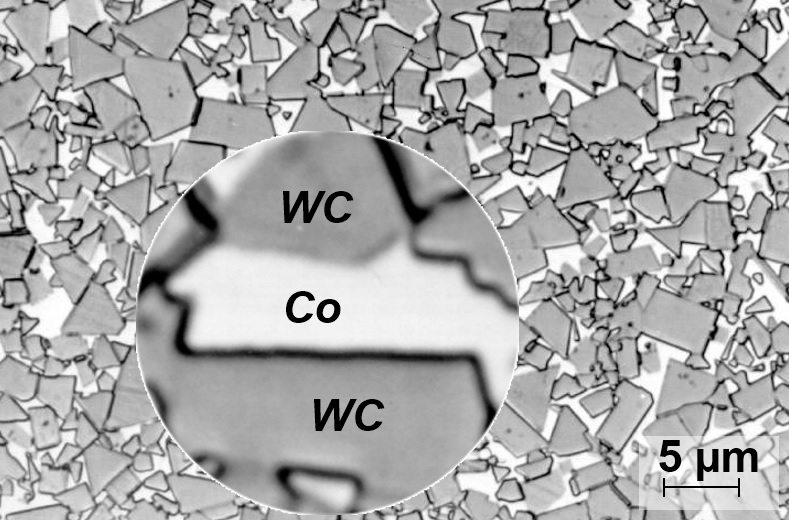

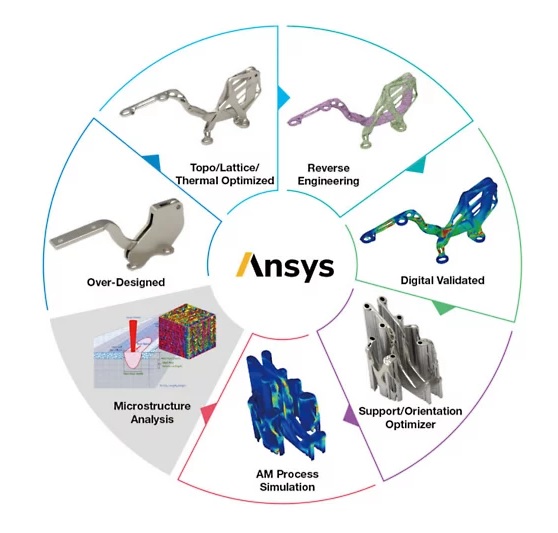

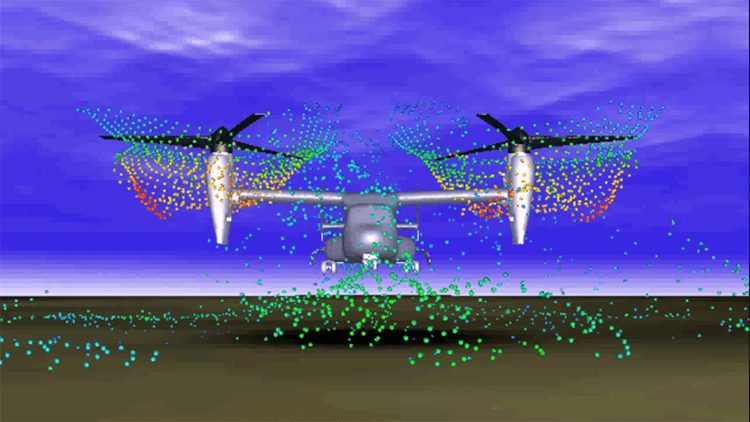

Designing plastic materials reinforced with glass and/or carbon fibers is a complex process that requires consideration of many factors, including the properties of the base plastic material, the type and length of fiber reinforcement, and the manufacturing process used to produce the final part. Advanced CAE software can be used to investigate the performance of these materials, including modal analysis, creep, stiffness, crash, and durability/fatigue.

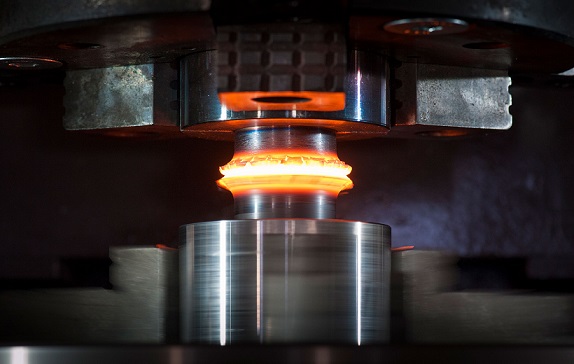

One of the most important challenges in using CAE software for the design of plastic materials is taking into account the effect of the manufacturing process on the performance of the final part.

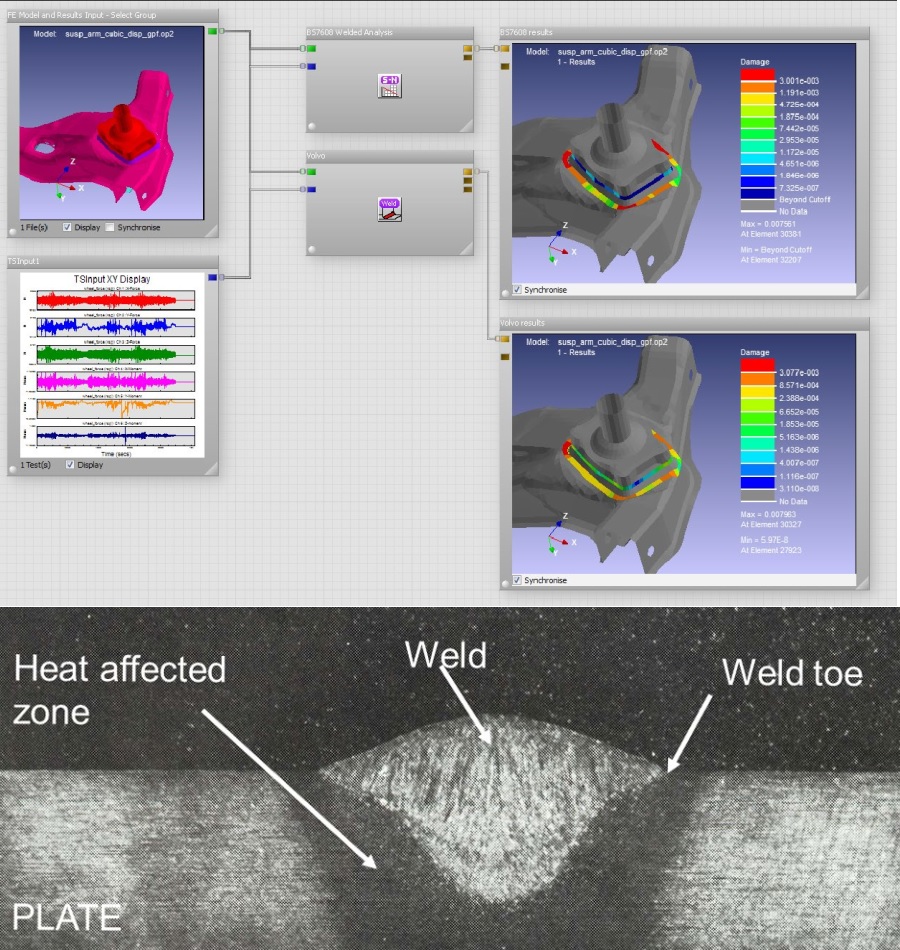

To address this challenge, it is important to use FEA solvers that is specifically designed to model the manufacturing process and its effects on the material properties. This may include using specialized software modules that can simulate the molding process, such as filling analysis, cooling analysis, and warpage analysis. Additionally, it may be necessary to perform experimental testing on samples produced using the same manufacturing process to validate the simulation results and ensure that the final part will meet the desired performance specifications.